0 引言

混凝是破坏胶体稳定性的过程,作为重要的水处理方法被广泛用于去除水中胶体类和部分可溶态污染物[1]。混凝效果不但影响后续单元运行情况,而且会影响出水水质、处理成本等[2]。混凝过程非常复杂,在原水水质和混凝剂种类确定时,其效果受pH值、水温、混/助凝剂投量、搅拌强度等影响。如何优化混凝工况获取最佳混凝效果,一直是水处理技术领域的热点。

以往多因素实验常通过控制变量进行,过程烦琐且难以分析因素间的交互影响[3-4]。响应面法采用多元二次回归方程拟合因素和响应值的函数关系,并以此寻求最优参数[5]。混凝效果常用浊度评价,但粒径、分形维数等描述絮体特性的微观指标才是本质因素。本文采用响应面法考察混/助凝剂投量、pH值、搅拌强度等与浊度、絮体特性间的关系,进而建立多因素交互作用的混凝模型并进行验证,为实际优化应用提供理论支持和技术指导。

1 材料与方法

1.1 实验材料

实验原水由蒸馏水和高岭土储备液混合而成。将200 g高岭土分散在1 L蒸馏水中,用0.1 mol/L的HCl溶液和0.1 mol/L的NaOH溶液调节pH值至7.5,高速搅拌0.5 h后静沉2 h,取上部悬浊液作为高岭土储备液。取800 mL储备液稀释至1 L作为实验原水(pH值为7.1,浊度为95.47 NTU)。混凝剂选用硫酸铝溶液(每10 g硫酸铝溶于1 L蒸馏水)。助凝剂选用PAM(每0.5 g PAM溶于1 L蒸馏水)。

1.2 实验方法

采用六联式搅拌机(DBJ-621型)进行实验,在各烧杯中加入1 000 mL原水,根据响应面法设定的边界条件(如表1所示)调节pH值、投加混/助凝剂。先快速搅拌2 min(搅拌强度为200 r/min),再慢速搅拌若干分钟,结束后立刻用移液管取混合液在显微镜下分析。静置沉降10 min后,取液面下2~3 cm处上清液测定浊度。

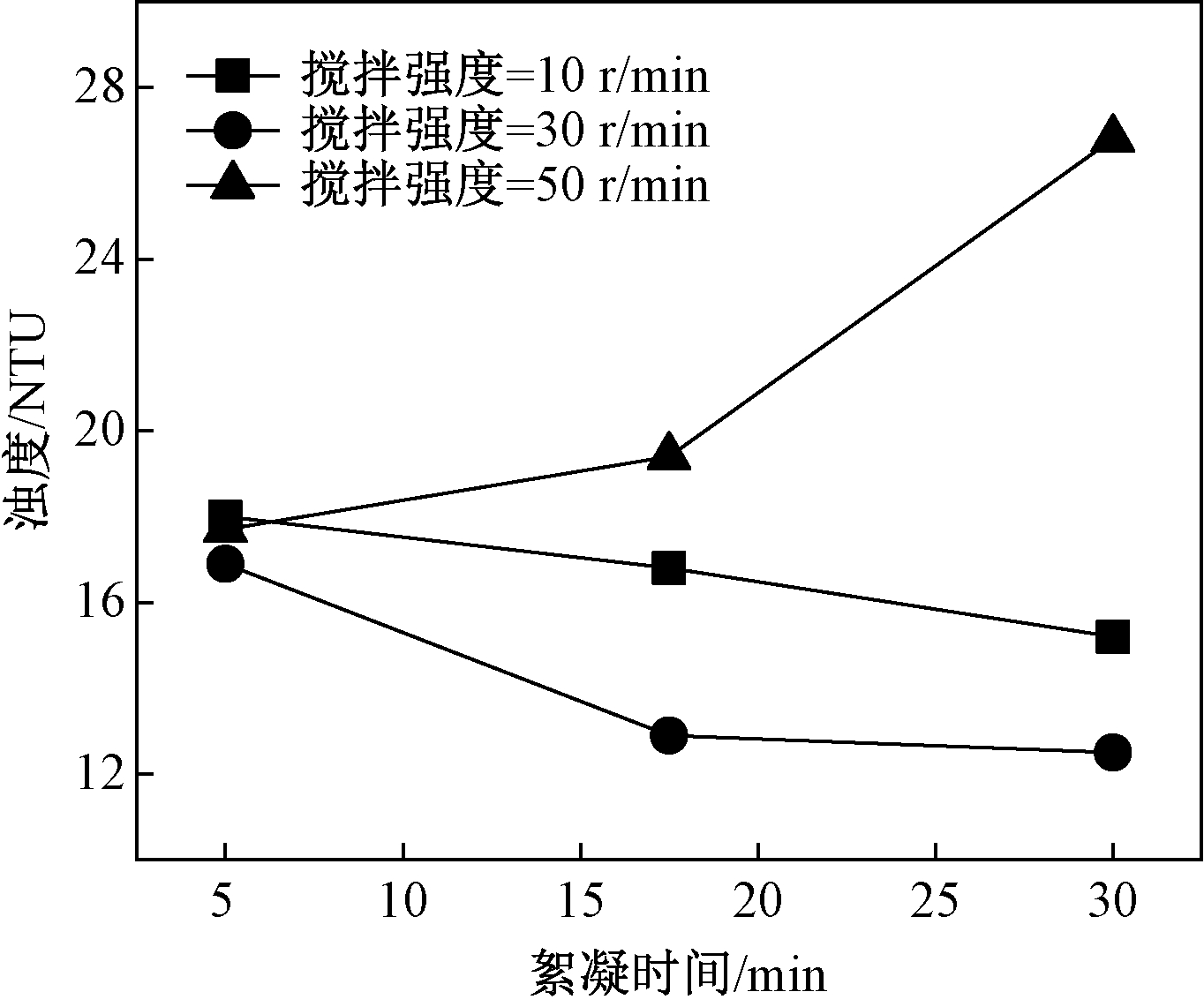

表1 响应面法混凝实验设计及结果

Table 1 Design and results of coagulation test by response surface methodology

实验组别X1pH值X2硫酸铝投量/(mg·L-1)X3搅拌强度/(r·min-1)X4絮凝时间/minX5PAM投量/(mg·L-1)Y1浊度/NTUY2平均粒径/μmY3分形维数1236.010.030.010.0040.4743.871.366.030.030.010.0023.5091.241.626.050.030.010.0013.10133.431.867.010.030.010.0035.9068.011.487.030.030.010.0018.87116.781.657.050.030.010.0012.91159.141.908.010.030.010.0032.6089.821.798.030.030.010.008.40205.531.948.050.030.010.0015.40128.311.548.030.010.05.0018.00187.931.518.030.010.017.5016.80213.871.648.030.010.030.0015.20249.201.748.030.030.05.0016.90224.431.608.030.030.017.5012.90277.811.878.030.030.030.0012.50598.491.818.030.050.05.0017.70228.001.678.030.050.017.5019.40215.831.848.030.050.030.0026.80194.381.836.030.030.030.01.017.60122.681.636.030.030.030.05.513.00316.861.816.030.030.030.010.013.10266.381.767.030.030.030.01.018.6084.411.617.030.030.030.05.59.20341.271.817.030.030.030.010.013.30230.921.728.030.030.030.01.017.30177.201.638.030.030.030.05.58.60359.101.838.030.030.030.010.014.30223.371.64

1.3 分析方法

采用WGZ-4000型浊度仪测定浊度;利用BX51TF型显微镜观察絮体形态;通过ImageView显微图像软件测量絮凝体投影周长、投影面积、平均粒径。分形维数计算公式如下[6-7]:

lg A=lg α+D2lg P。

(1)

式中:A为絮体的投影面积,μm2;P为投影周长,μm;D2为二维分形维数;α为比例常数,由絮体性质决定。

2 结果与讨论

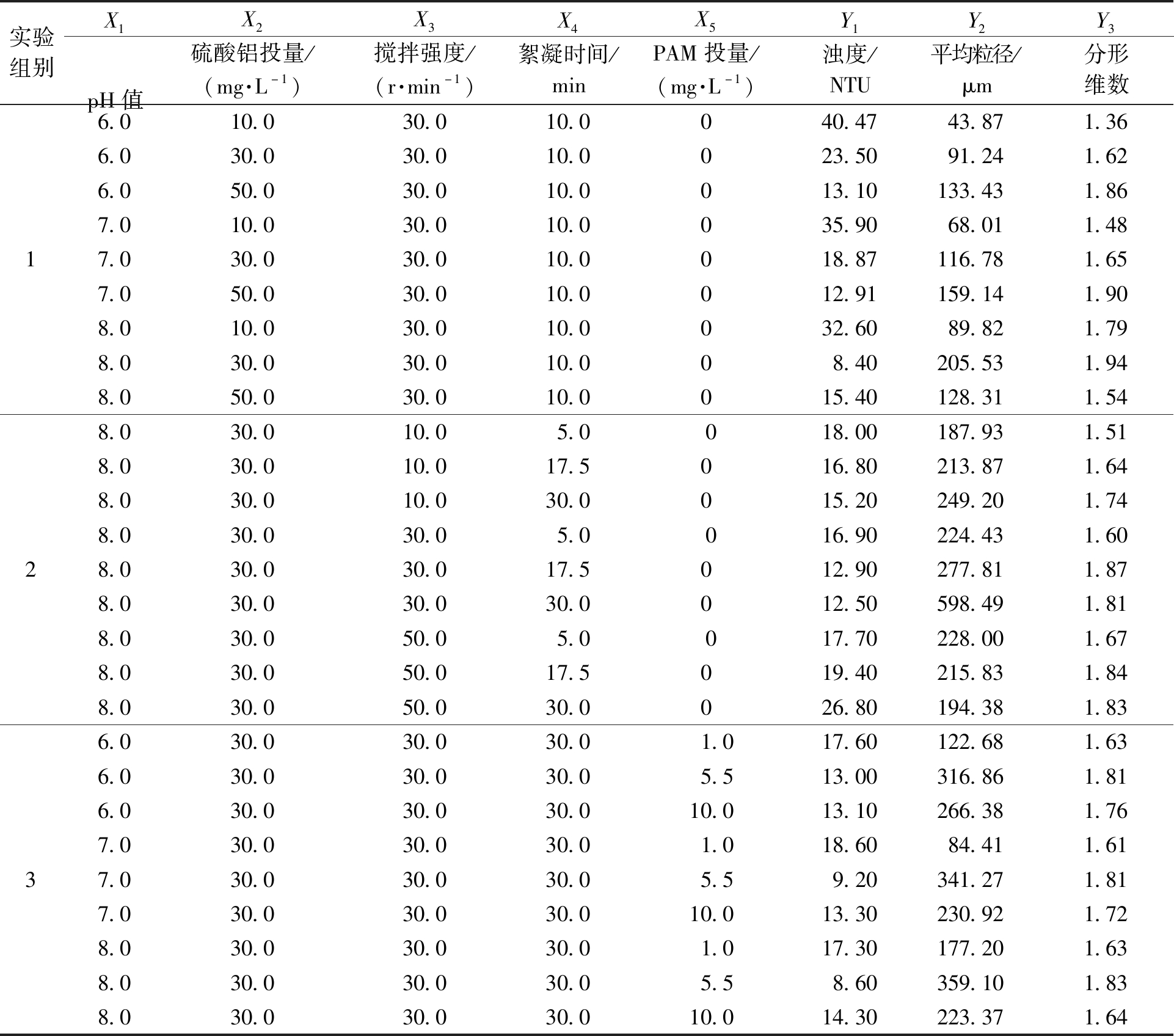

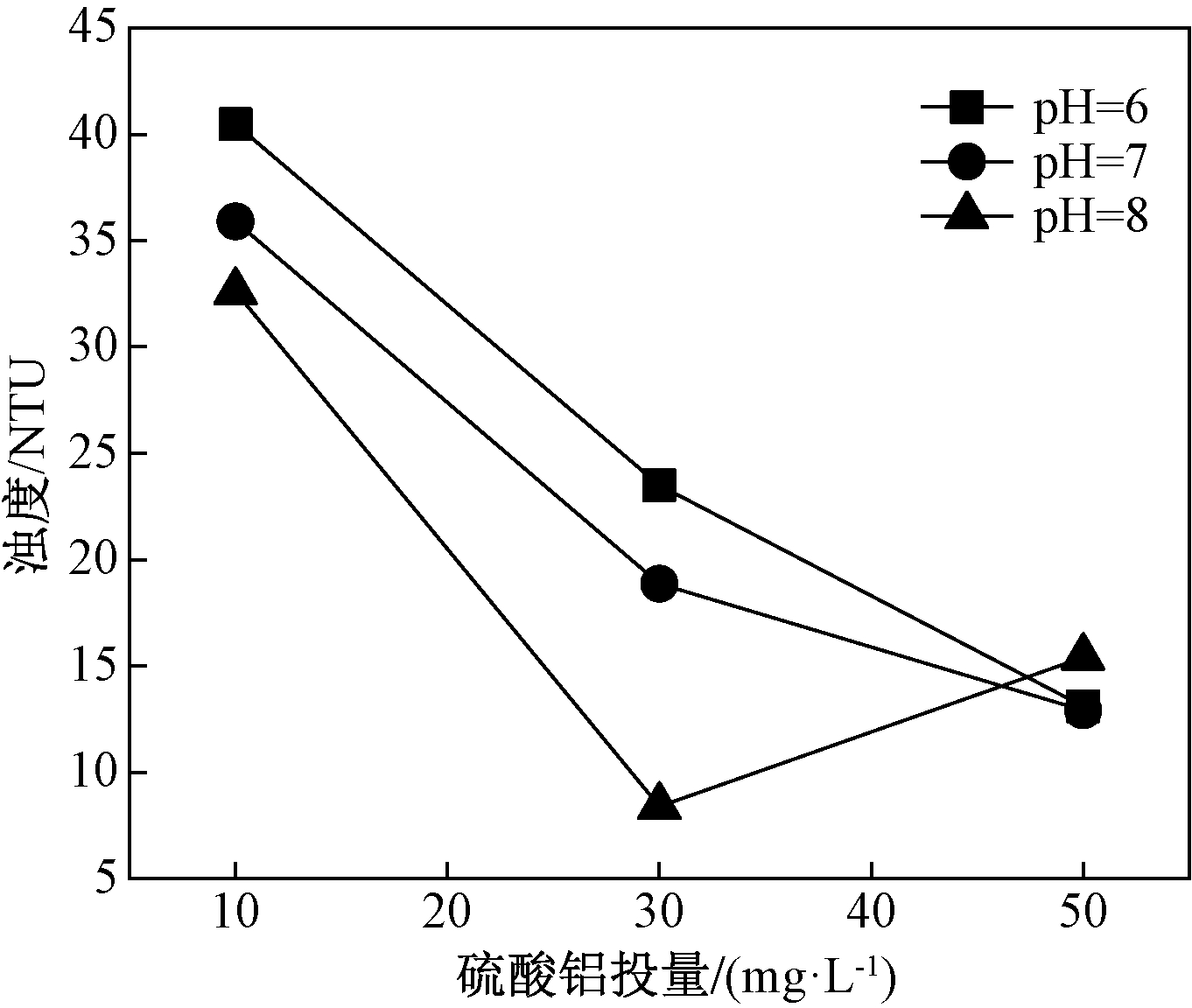

2.1 pH值与硫酸铝投量对混凝效果的影响

pH值与硫酸铝投量对混凝效果影响如图1所示。由图1可见,在pH值为6~7时,出水浊度随着硫酸铝投量增加而减小。当pH值在弱碱性时,各投量下平均出水浊度最低[8]。本实验在pH值为8、硫酸铝投量为30 mg/L时出水浊度最低,去除率为91.2%。pH值会影响Al3+的水解产物形态,当pH值为6~8时,其水解产物以氢氧化铝聚合物[Al(OH)3]n为主,Al6(OH)153+、Al(OH)4-等为辅。此时混凝过程中吸附架桥和电性中和机理起主要作用[9],正电荷高分子水解物质吸附负电荷胶体形成絮体颗粒。在pH值为6~7时絮体粒径随着投量增加而增大,出水浊度与絮体粒径、二维分形维数呈现负相关(如图2所示)。硫酸铝投量少时难以形成絮体,增大投量可以强化混凝效果。当pH值为8且硫酸铝投量为50 mg/L时,分形维数和平均粒径均显著下降。这是因为投量过多会导致胶粒被包卷而重新稳定[10]。

图1 不同pH值和硫酸铝投量下浊度变化

Figure 1 Variation trend of turbidity with different pH value and aluminum sulfate dosage

图2 不同pH值和硫酸铝投量下絮体特性变化

Figure 2 Characteristics of flocs with different pH and aluminum sulfate dosage

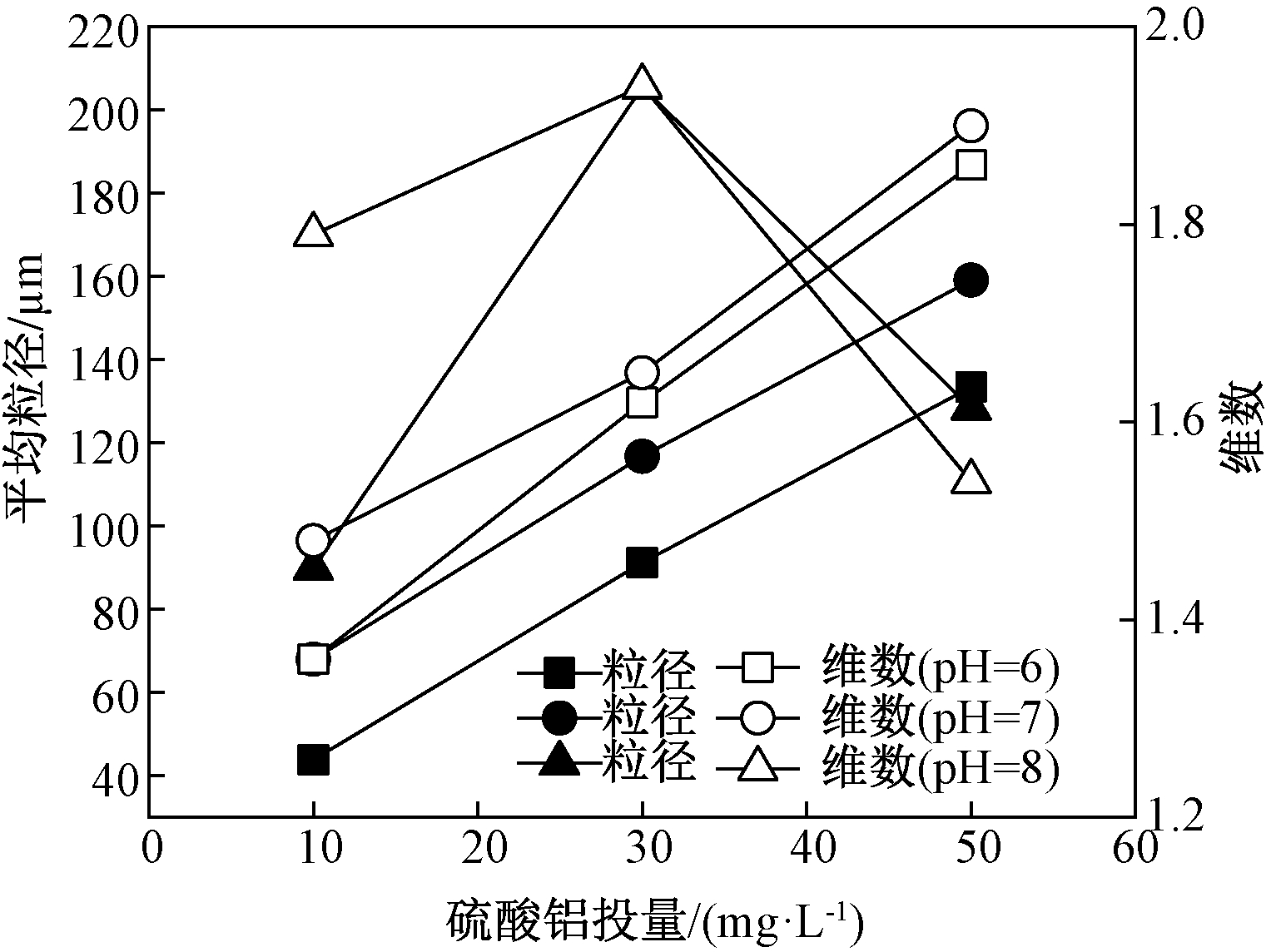

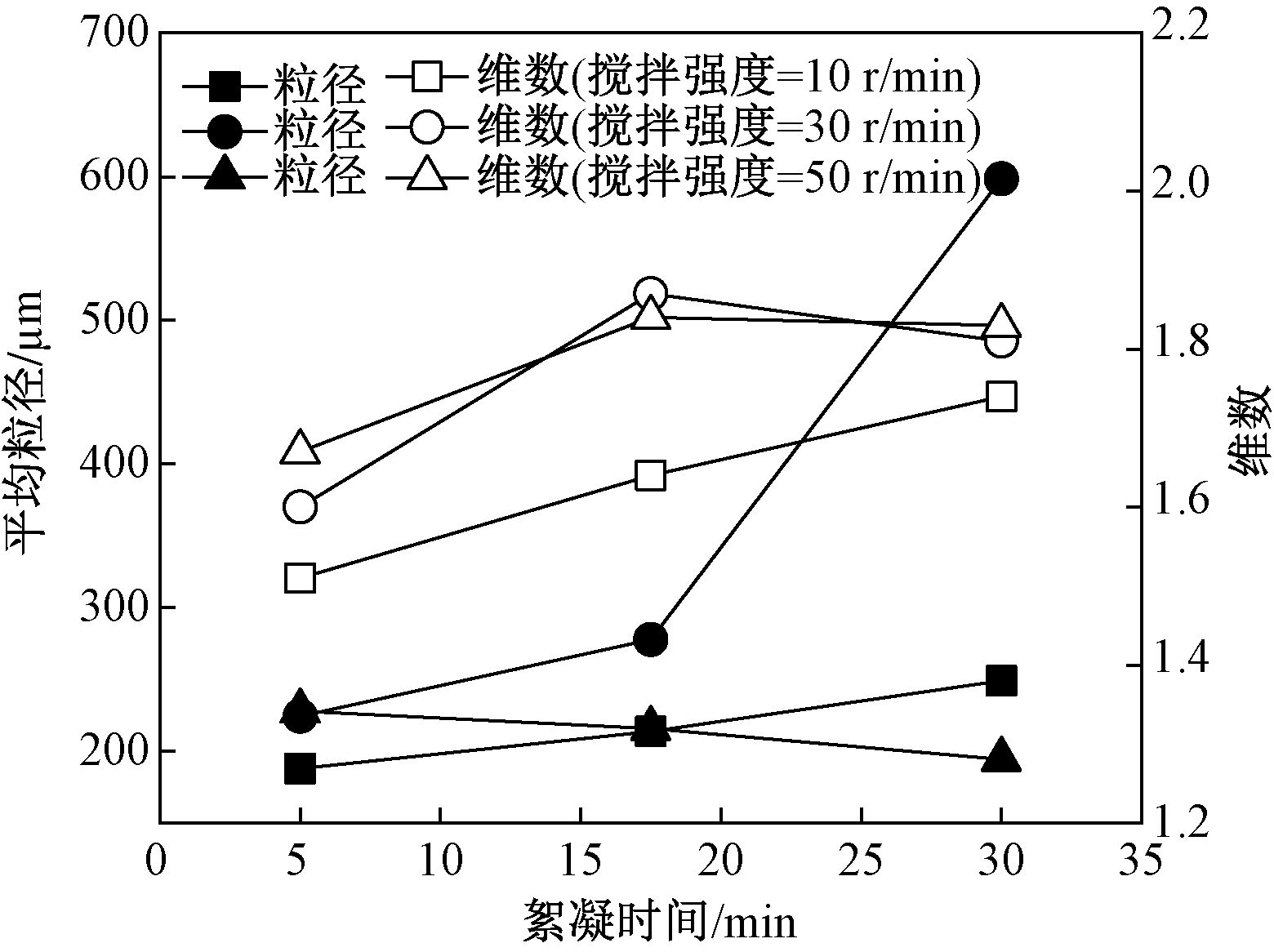

2.2 搅拌强度与絮凝时间对混凝效果的影响

搅拌强度与絮凝时间对混凝效果的影响如图3所示。由图3可见,当絮凝时间为5 min时,不同转速下平均出水浊度接近;当搅拌强度为10~30 r/min时,出水浊度随絮凝时间增加逐渐减小;当搅拌强度提升至50 r/min时,出水浊度随絮凝时间增加而上升。本实验当搅拌强度为30 r/min、絮凝时间为30 min时,出水浊度最低,去除率达到86.9%。机械搅拌产生的水流剪切作用会导致颗粒碰撞发生同向絮凝,适度搅拌能使硫酸铝与悬浮颗粒充分接触。当转速为10~17.5 r/min时,随着絮凝时间增加,二维分形维数和平均粒径逐渐增大(如图4所示),表明絮体结构复杂化,黏附胶粒效果好。当搅拌强度为30 r/min,絮凝时间增大至30 min时,分形维数在1.8~1.9之间波动,平均粒径由224.43 μm增大至598.49 μm。说明水力条件有利于絮体生长,且絮体的形态结构先趋于稳定,絮体粒径仍持续增加。由图4可知,搅拌强度为50 r/min时形成的絮体粒径很小,且随着搅拌时间增加有下降趋势,分形维数由1.67增大至1.84后趋于稳定。当搅拌强度过大时,絮体结构逐渐复杂化,但由于水流剪切力过大导致絮体破碎且难以恢复而降低混凝效果。

图3 不同搅拌强度和絮凝时间下浊度变化

Figure 3 Variation trend of turbidity with different stirring intensity and flocculation time

图4 不同搅拌强度和絮凝时间下絮体特性变化

Figure 4 Characteristics of flocs with different stirring intensity and flocculation time

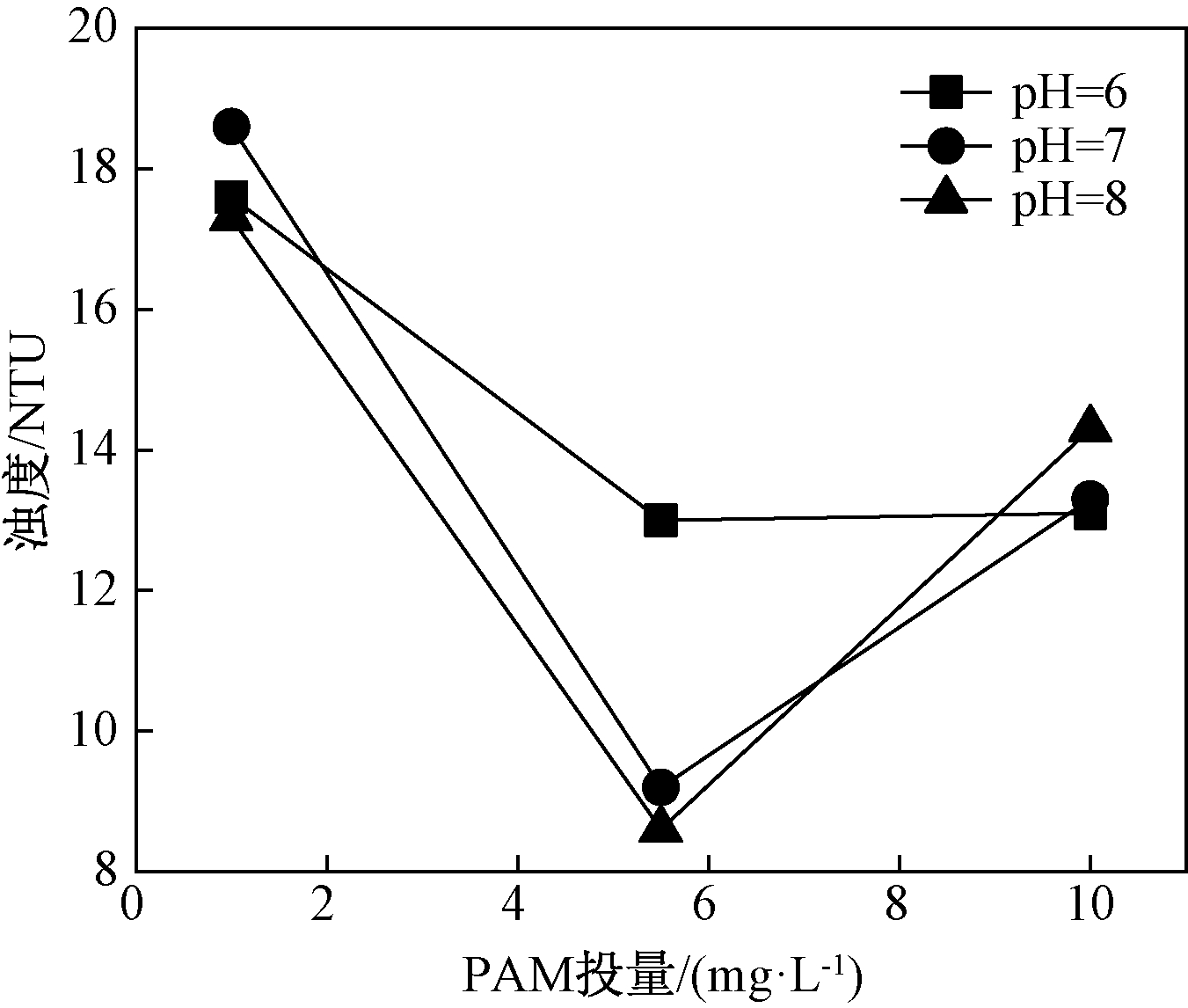

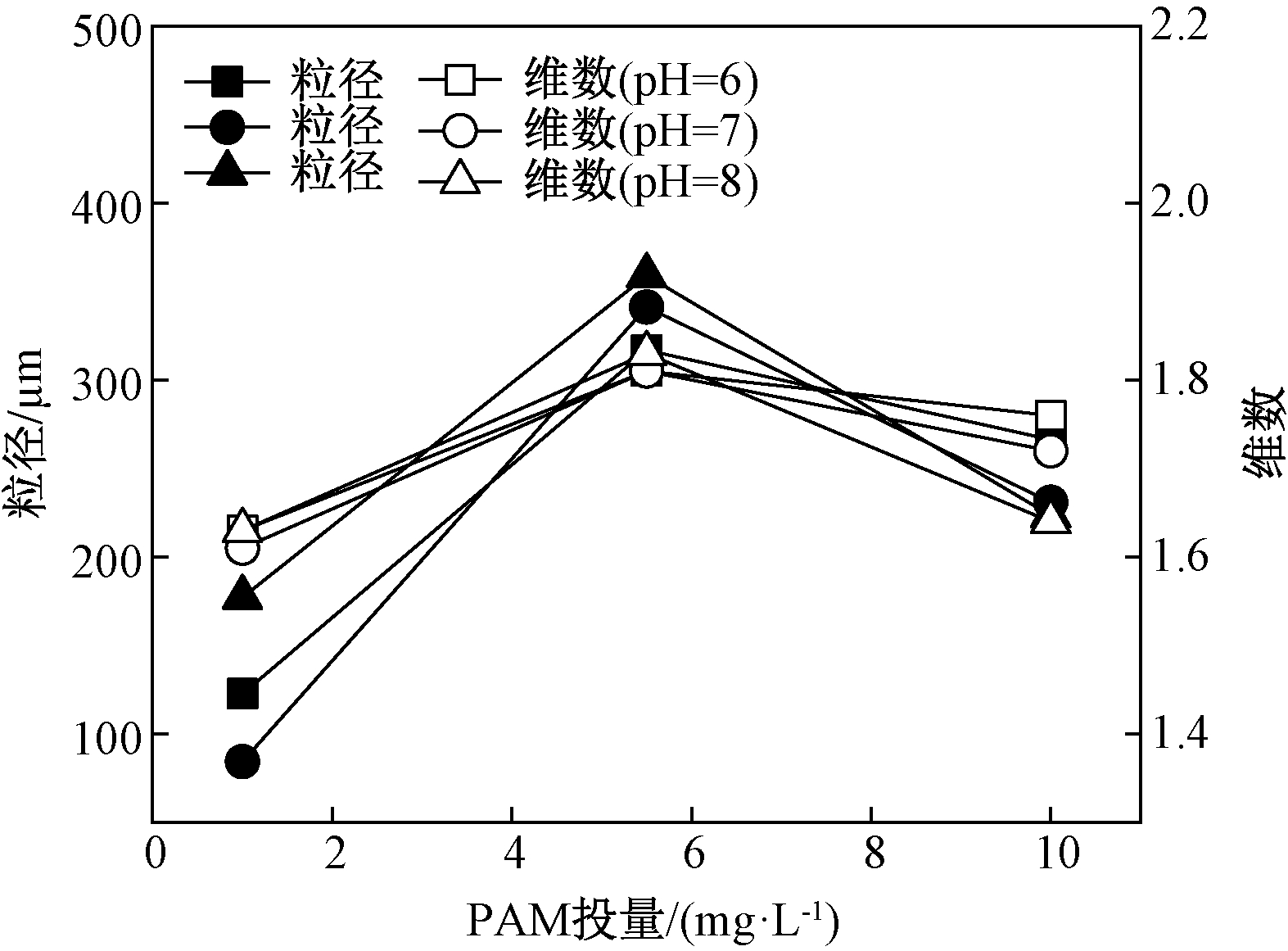

2.3 pH值与PAM投量对混凝效果的影响

pH值与PAM投量对混凝效果的影响如图5所示。从图5看出,不同pH值下出水浊度随着PAM投量增加均呈先下降后上升的趋势。当pH值为7~8、PAM投量相同时平均出水浊度相近。本实验当pH值为8、PAM投量为5.5 mg/L时浊度去除率达到90.36%。由图5可见,PAM投量较pH值对混凝效果影响更大。PAM是丙烯酞胺单体的有机高分子聚合物,对胶体表面具有强烈吸附作用,通过桥联形成絮体,混凝效果受pH值影响较小。随着PAM投量增大,絮体粒径和结构复杂度均呈上升趋势(如图6所示)。当投量继续增大时,胶体吸附面被覆盖进而形成再稳定状态[11],导致混凝效果变差。

图5 不同pH值和PAM投量下浊度变化

Figure 5 Variation trend of turbidity with different pH value and PAM dosage

图6 不同pH值和PAM投量下絮体特性变化

Figure 6 Characteristics of flocs with different pH value and PAM dosage

2.4 混凝模型构建与验证

分别以pH 值、助凝剂投量、搅拌强度、絮凝时间和助凝剂投量为自变量,以出水浊度为因变量,采用Design-Expert统计分析软件进行多元回归拟合,得到以浊度为响应值的二次多项式回归方程,代入实验数据后得到式(2):

Y=45.36-1.46X1-0.67X2-0.34X3-

0.28X4-1.39X5+0.03X1X2+0.004 X3X4+

0.03X1X5-0.06X12+0.01X22+0.004 X32+

0.004 X42+0.10X52。

(2)

利用Design-Expert中参数优化功能得到最优工况:pH值为8.00、硫酸铝投量为21.47 mg/L、搅拌强度为31.41 r/min、絮凝时间为19.37 min、PAM投量为5.75 mg/L。在最优工况下进行3组平行实验,平均出水浊度为12.01 NTU,与预测浊度为11.69 NTU的相对误差为2.66%,表明模型可以用来预测出水浊度[12]。进一步考察各因素对混凝效果的影响权重,分别对5个自变量求导,代入最佳条件得到导数值,发现影响权重由大到小依次是PAM投量、pH值、硫酸铝投量、搅拌强度、絮凝时间。显然pH值和投药量的交互作用对混凝效果的影响最大。

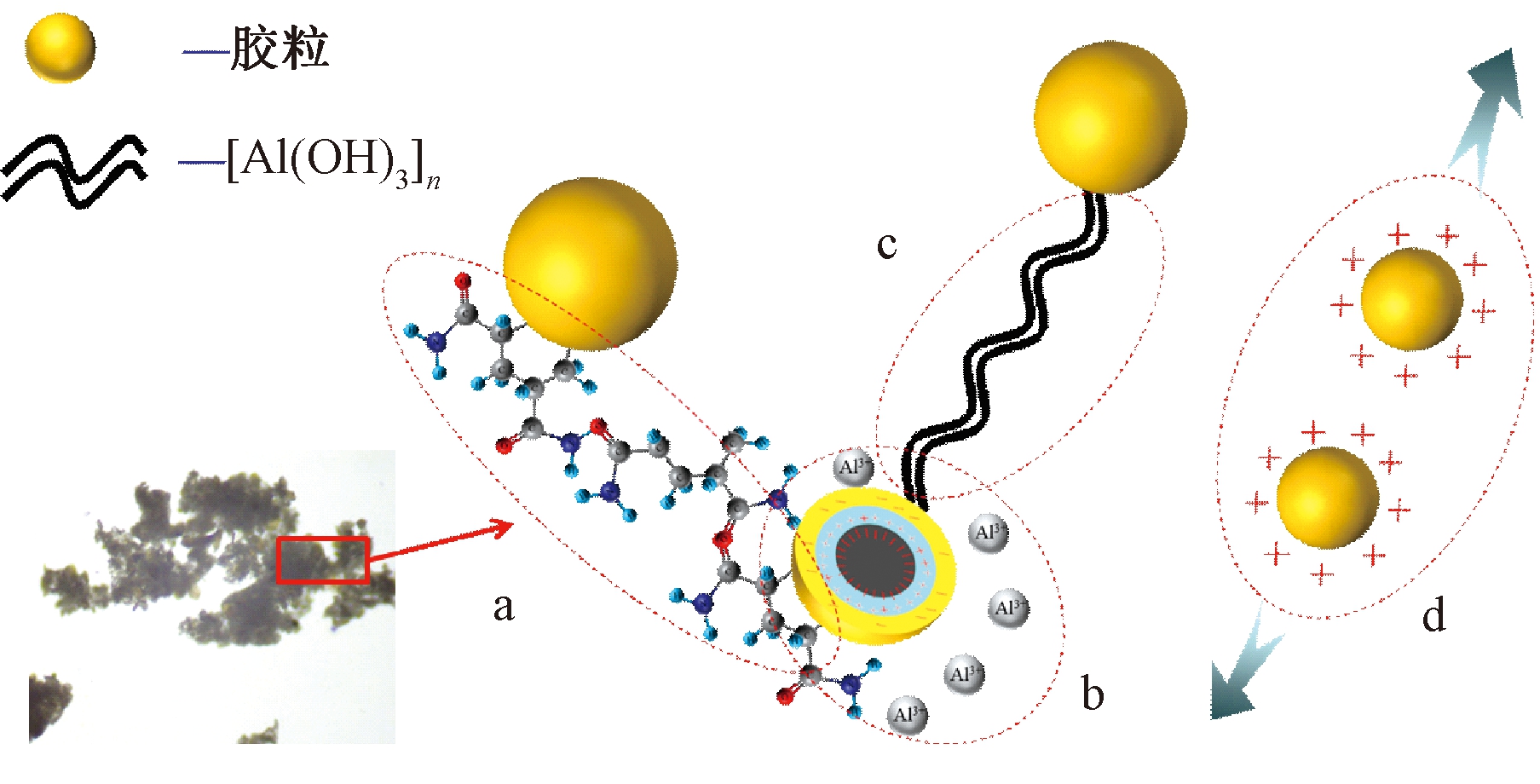

在原水水质不变时,混凝效果主要与水解产物及胶粒与混凝剂间的相互作用有关[13]。PAM是线状有机高分子聚合物,通过吸附架桥与胶粒形成空间网状,进而显著改善絮体结构(图7中a部分)[14-15]。水中胶粒一般带负电[16],在最优混凝条件下主要通过电性中和(图7中b部分)、吸附架桥(图7中c部分)作用使胶粒脱稳[17]。此时水解产物中含有大量氢氧化铝聚合物[Al(OH)3]n,吸附胶粒发生共沉淀。最优条件下投药量适中,发生投量过度造成的胶体保护作用的概率很低(图7中d部分)。由以上分析可见,实际工程中水处理规模大且pH值相对稳定,优化混凝剂、助凝剂投量是强化混凝效果的有效手段。

图7 混凝模型示意

Figure 7 Illustration of coagulation model

3 结论

(1)利用响应面法对实验条件进行优化,得出最优的硫酸铝混凝处理高岭土原水工况条件:pH值为8.00、硫酸铝投量为21.47 mg/L、搅拌强度为31.41 r/min、絮凝时间为19.37 min、PAM投量为5.75 mg/L。进而建立了以浊度为响应值的二阶回归模型,可以预测不同工况条件下的出水浊度。

(2)在影响混凝效果的众多因素中,pH值和硫酸铝(PAM)投量对混凝效果起决定性作用,搅拌强度影响絮体形成速率和最终形态,随着絮凝时间的延长,絮体稳定性波动较小,絮体粒径随之增加。实际工程应用中可根据模型确定最优投药量、最优搅拌强度和絮凝时间。

[1] AMUDA O S,AMOO I A.Coagulation/flocculation process and sludge conditioning in beverage industrial wastewater treatment[J].Journal of hazardous materials,2007,141(3):778-783.

[2] 王东升,刘海龙,晏明全,等.强化混凝与优化混凝:必要性、研究进展和发展方向[J].环境科学学报,2006,26(4):544-551.

WANG D S,LIU H L,YAN M Q,et al.Enhanced coagulation vs.optimized coagulation:a critical review[J].Acta scientiae circumstantiae,2006,26(4):544-551.

[3] 贾定田.影响混凝剂聚合硫酸铁和聚合氯化铁稳定性的原因及机理的研究[D].广州:暨南大学,2017.

JIA D T.Causes and mechanisms study on the stability of polymeric ferric sulfate and polymeric ferric chloride as coagulants[D].Guangzhou:Jinan University,2017.

[4] 陈俊英,周航宇,唐焕妍,等.响应面法优化纤维素基载体固定糖化酶的研究[J].郑州大学学报(工学版),2019,40(2):66-71.

CHEN J Y,ZHOU H Y,TANG H Y,et al.Optimization for cellulose carrier immobilized glucoamylase by response surface methodology[J].Journal of Zhengzhou university (engineering science),2019,40(2):66-71.

[5] GHAFARI S,AZIZ H A,ISA M H,et al.Application of response surface methodology (RSM) to optimize coagulation-flocculation treatment of leachate using poly-aluminum chloride (PAC) and alum[J].Journal of hazardous materials,2009,163(2/3):650-656.

[6] 王玉,范跃华,王姣,等.混凝絮凝体的分形与沉降特性实验研究[J].安全与环境工程,2006,13(3):72-75.

WANG Y,FAN Y H,WANG J,et al.Experimental research on the properties of fractal and sedimentation of aggregate flocs[J].Safety and environmental engineering,2006,13(3):72-75.

[7] 常颖,张金松.絮凝体分形维数投药控制研究[J].环境污染治理技术与设备,2006(4):46-49.

CHANG Y,ZHANG J S.Study on dosage control by flocs fractal dimension[J].Techniques and equipment for environmental pollution control,2006(4):46-49.

[8] 李祥林,钟建东.响应面法优化聚合氯化铝混凝效果的研究[J].中国给水排水,2015,31(21):141-143.

LI X L,ZHONG J D.Process optimization of PAC coagulation effect by response surface methodology[J].China water &wastewater,2015,31(21):141-143.

[9] 朱磊.絮凝体分形维数的实验研究[D].武汉:武汉科技大学,2011.

ZHU L.Experimental study on fractal dimension of the aggregates flocs[D].Wuhan:Wuhan University of Science and Technology,2011.

[10] WEI N,ZHANG Z G,LIU D,et al.Coagulation behavior of polyaluminum chloride:effects of pH and coagulant dosage[J].Chinese journal of chemical engineering,2015,23(6):1041-1046.

[11] 谢慧娜,李杰,朱雪燕,等.响应面法优化混凝处理夏季高浊度黄河水[J].工业水处理,2020,40(2):45-49.

XIE H N,LI J,ZHU X Y,et al.Optimization of high turbidity Yellow River water in summer by coagulation treatment using response surface methodology[J].Industrial water treatment,2020,40(2):45-49.

[12] 孙旸,地里百尔·努尔,林晓琼,等.纤维素酶处理玉米秸秆工艺条件的优化[J].吉林农业大学学报,2017,39(5):544-550.

SUN Y,NUR D,LIN X Q,et al.Optimization of process conditions of maize stalk treated with cellulase[J].Journal of Jilin agricultural university,2017,39(5):544-550.

[13] 严煦世,范瑾初.给水工程[M].4版.北京:中国建筑工业出版社,1999.

YAN X S,FAN J C.Water supply engineering[M].Beijing:China Architecture &Building Press,1999.

[14] MA J Y,XIA W,FU X,et al.Magnetic flocculation of algae-laden raw water and removal of extracellular organic matter by using composite flocculant of Fe3O4/cationic polyacrylamide[J].Journal of cleaner production,2020,248:119276.

[15] 卢楠.微污染水强化混凝试验研究[D].济南:山东建筑大学,2014.

LU N.Experimental investigation on enhanced coagulation for micro-polluted water[D].Jinan:Shandong Jianzhu University,2014.

[16] 夏玮,张蕊,吴根宇,等.微污染源水的混凝处理及絮体粒径研究[J].土木与环境工程学报(中英文),2020,42(4):185-193.

XIA W,ZHANG R,WU G Y,et al.Coagulation treatment of micro-polluted water and study of floc size[J].Journal of civil and environmental engineering,2020,42(4):185-193.

[17] TALAIEKHOZANI A,TALAEI M R,REZANIA S.An overview on production and application of ferrate (VI) for chemical oxidation,coagulation and disinfection of water and wastewater[J].Journal of environmental chemical engineering,2017,5(2):1828-1842.